Jagnath Plot, Rajkot, Gujarat

- GST NO. : 24AFMPR2626G1ZE

5 Nos (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Cast Iron ASTM Grade 40, GR40 |

| Mfg Process | Sand Casting, Centrifugal Casting |

| Finishing | Honned, Polished, Grinning, Chromed, Nitrated |

| Click to view more | |

Preferred Buyer From

| Location | All Countries Except India |

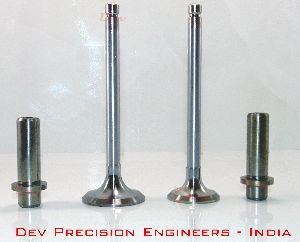

Product Details

We also accept the customized orders of our clients and manufacture these products in accordance with the samples and drawings with the given material & coating.

Cylinder Sleeves, made of gray cast-iron, ought to have desired casting and machining qualities, viz. strength, toughness, hardness and wear resistance. These are mainly of two types – Dry sleeves and Wet sleeves. The sleeves are ‘cast-in fit’, force (press) fit or slip fit. The interference between its outer diameter and bore-hole walls depends on fit-type from 0.050 to 0.075 mm. These are available in wide range suitable for light, medium and heavy duty application.

In order to meet with industrial quality standards, we manufacture these sleeves from sand casting and centrifugal casting, which enables us to maintain the uniform hardness all over. Apart from this, we also keep into consideration various factors including distortion-less bore and low thermal expansion to meet with the requirements of our clients. These sleeves are available in semi finished as well as full finished sizes. Cross honing is done on the full finished products to make the inner bore distortion-less. The inner bores are cross honed to provide maximum smoothness to the surface, that in turn reduces friction, when this inner bore is contacted with Piston Rings.

Quality:

- A very good plateau honing and cylindrical grinding that matches the geometrical parameters.

- Manufactured with chromium and nickel elements maintaining the BS4K6 material standard.

- Stringent material along with microstructure analysis of all the batches individually.

- Complete dimensional inspection of the finished components included in the process.

- Inspection of honing angle, structure and surface roughness at a random.

- Tests of profiles, tensile strength and crack detection at regular intervals in a random way.

- Manufacturing experience for the past 25 years and an expertise with single roof manufacturing outlet.

- A very wide range and suitable for up to 1500 models for worldwide cars, trucks, tractors and industrial engines.

Process

In the centrifugal casting process, the molten metal is poured into a metal mould or die which is revolving at a high speed. The centrifugal force causes the metal to distribute itself evenly around the die. The resulting casting are of much finer grain and free from blow holes or porosity. A further important advantage is that the impurities, being lighter than the iron, are forced centrifugally to the bore surface from which they are removed by machining.

Looking for "Cylinder Sleeves" ?

Explore More Products